Products

-

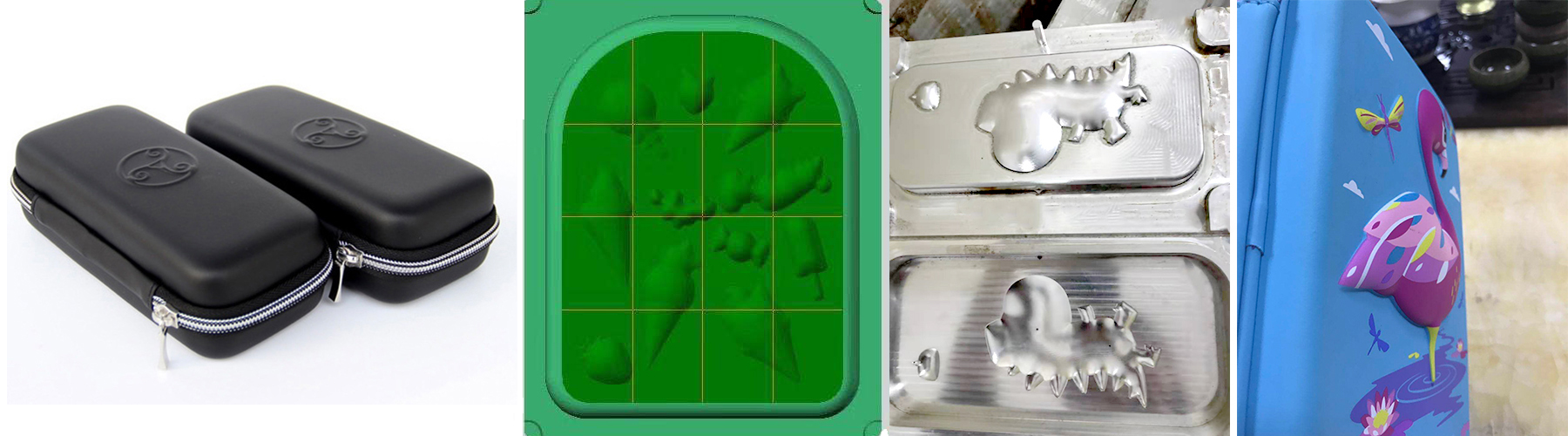

Protective Cases and Bags

Lightweight and impact-resistant protective cases made of EVA resin.

They are waterproof and durable, protecting various devices and small items safely. -

-

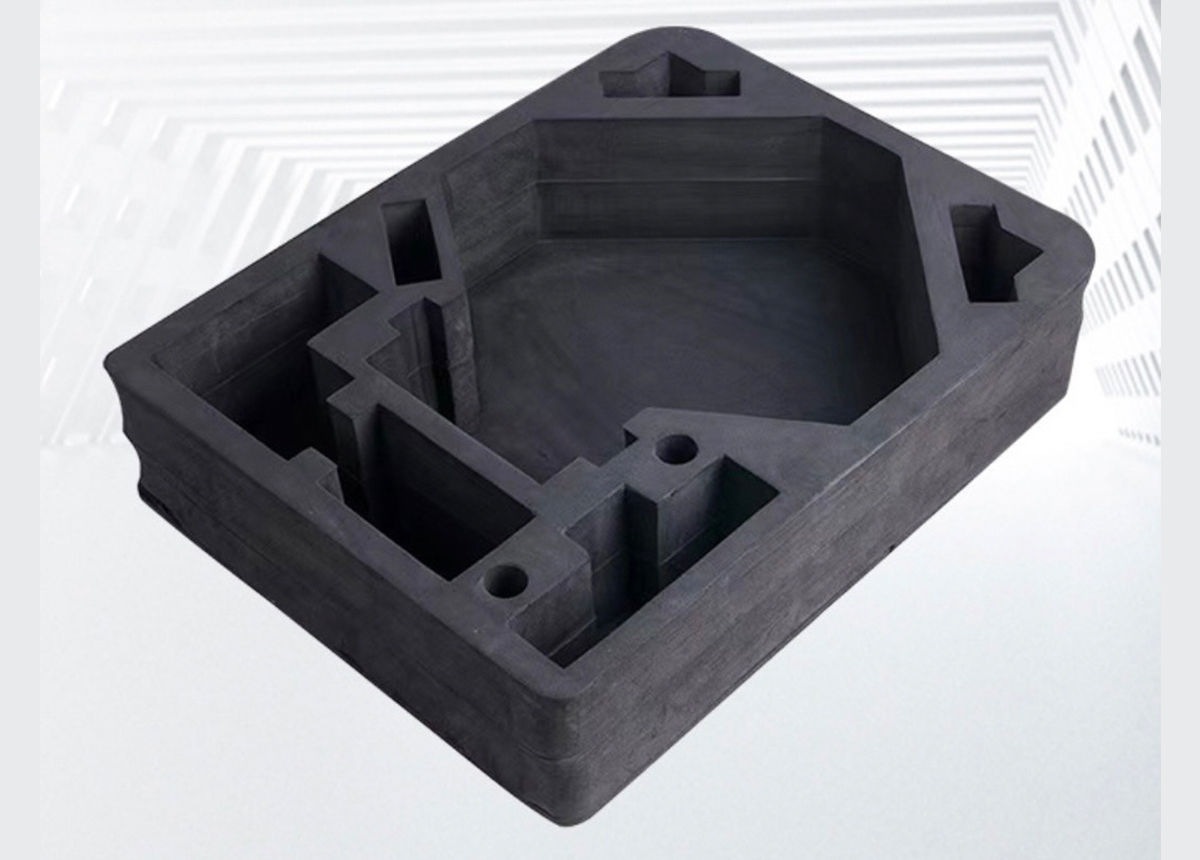

Cushioning Materials

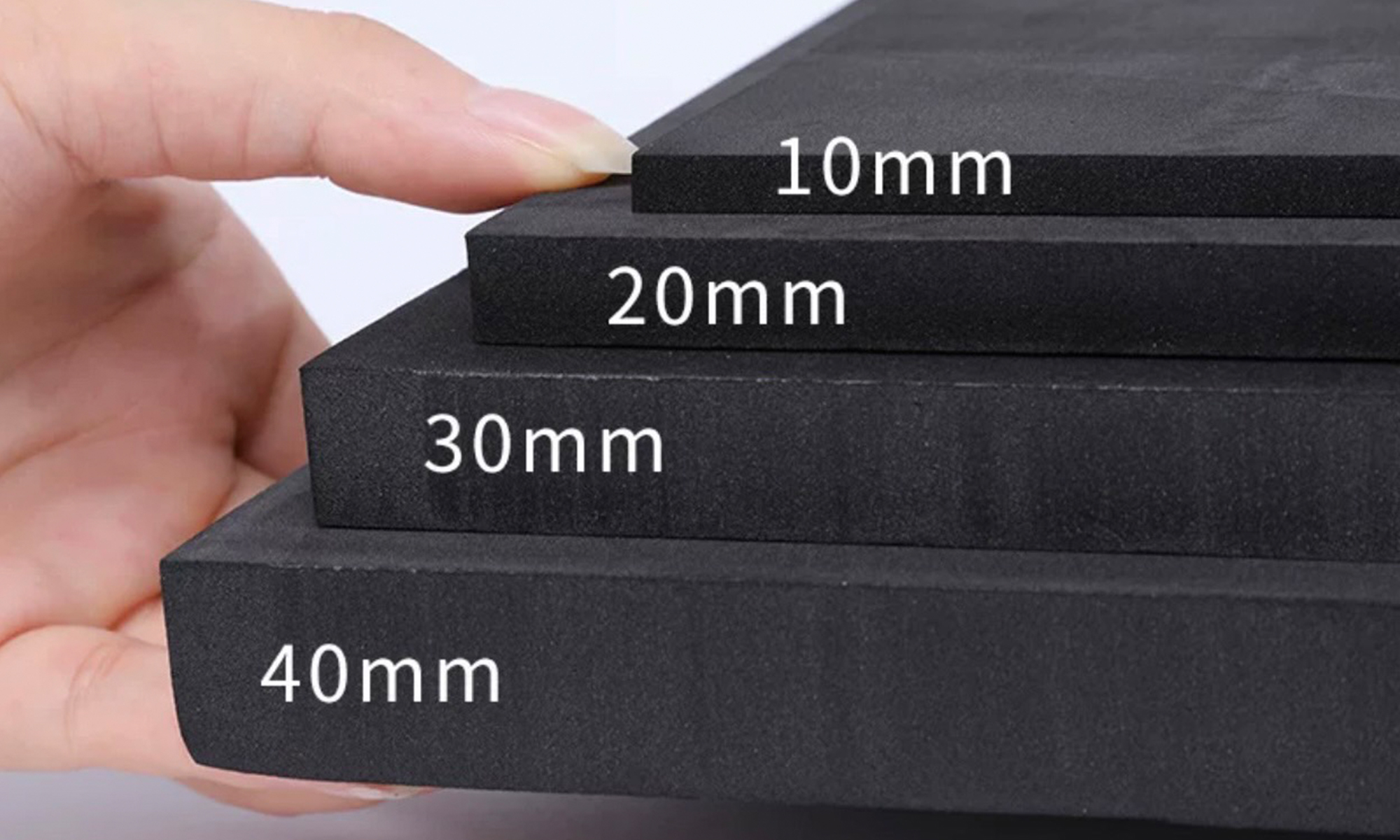

Cushioning materials made of EVA resin with excellent shock absorption.

They are environmentally friendly and recyclable, available in various shapes and thicknesses.

Ideal for protecting products and packaging. -

-

Various Parts and Components

Various parts and components can be molded from EVA resin.

Ideal for use as accessory parts for products or as cushioning materials.

Capable of molding complex shapes, large sizes, and three-dimensional forms.

Please consult with us for your specific needs. -

Technology

-

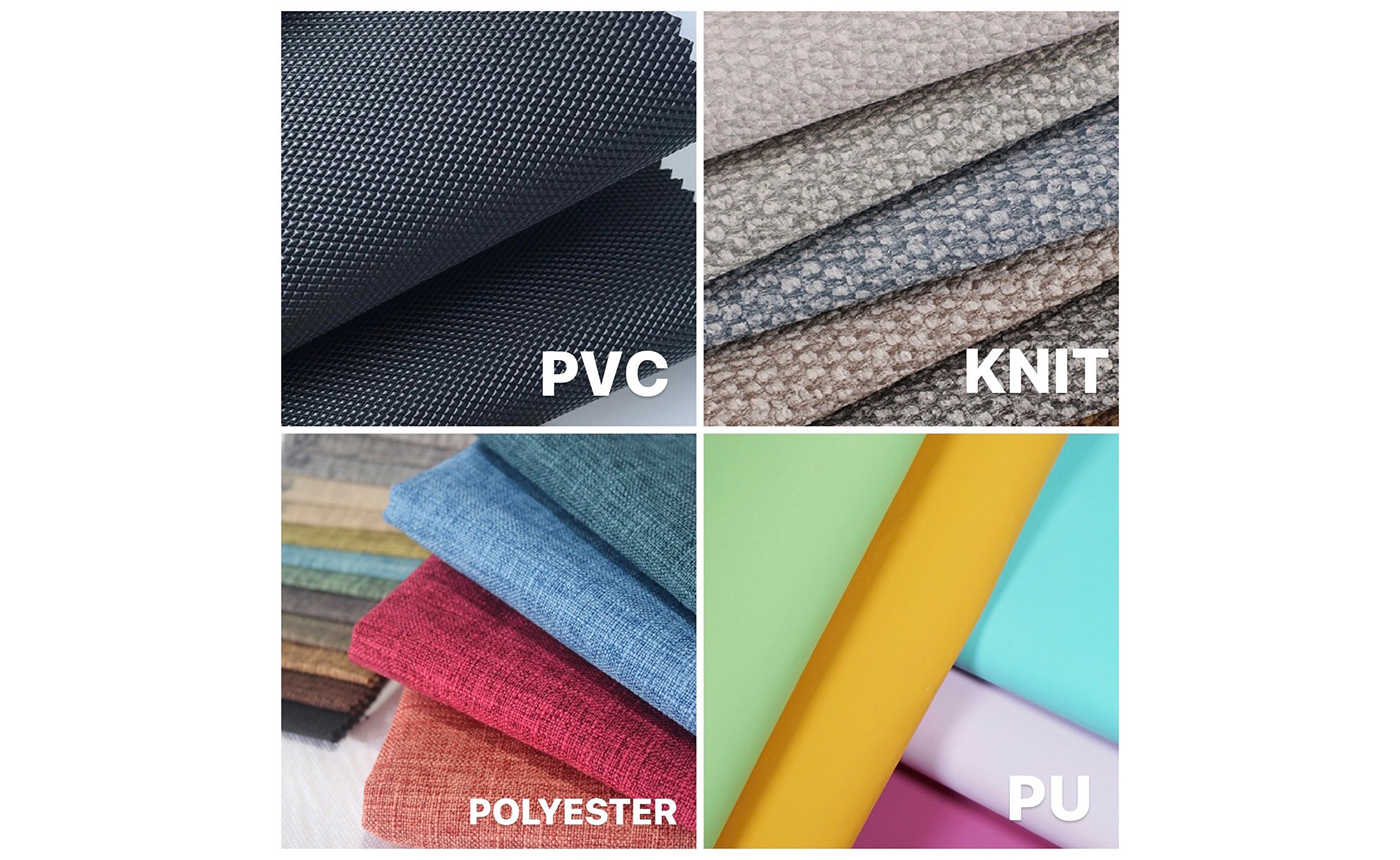

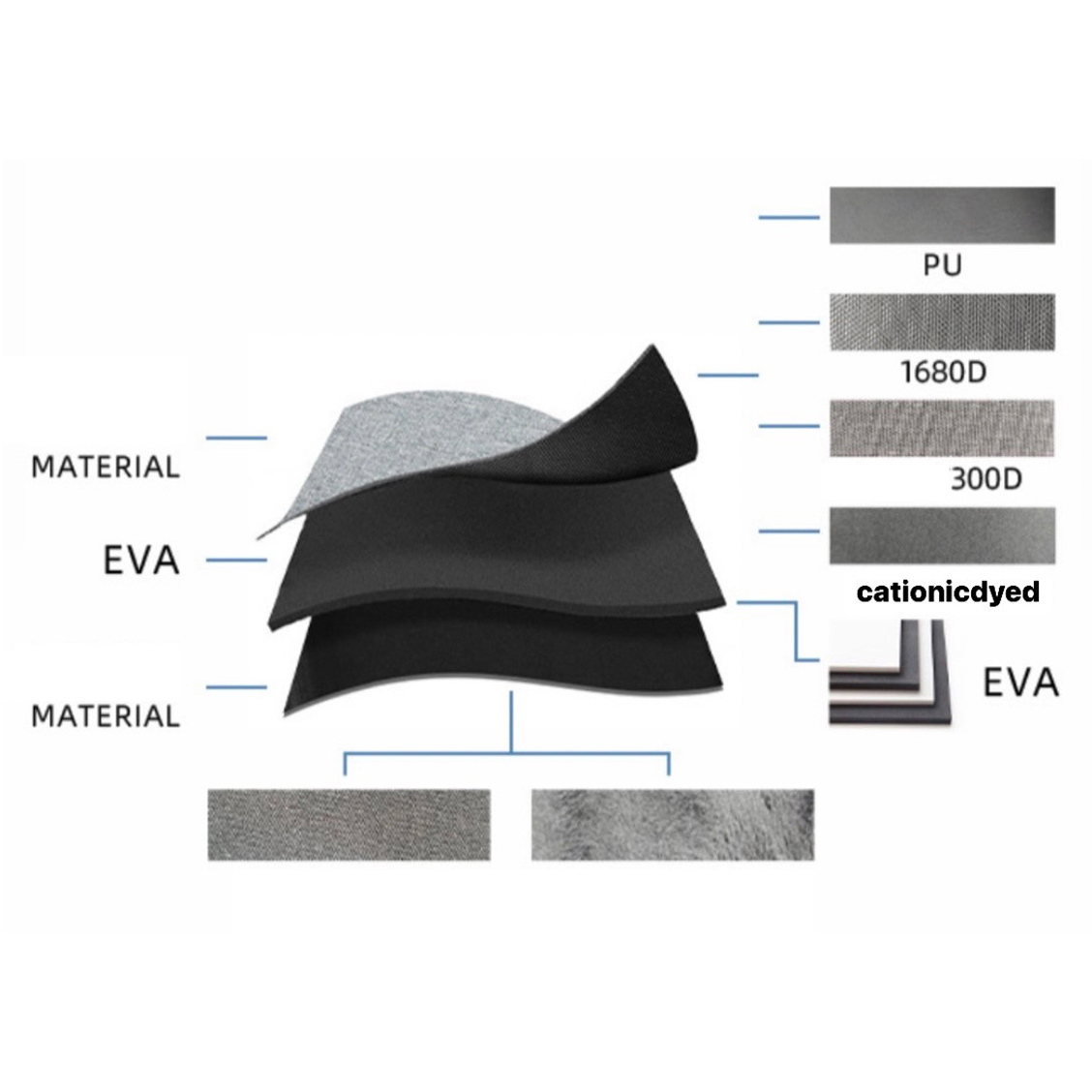

Fabric Attachment

By bonding EVA with a fabric using a special glue and then thermoforming, the product becomes fully integrated. It enables permanent adhesion without sewing or riveting, and to reduce labor time and costs because of only once thermoforming. Almost any fabric can be attached, allowing for a variety of designs.

-

Heat Transfer

This technique involves placing a heat transfer film on EVA and applying heat to transfer the printed ink onto the EVA. Compared to direct printing on materials or fabrics, it is possible to achieve high print quality and reproduce various colors and designs.

-

Silk Screen Printing

It is possible to add logos or text as single points, and to choose the color and glossiness. It is a cost-effective and highly recommended option.

-

Convex Surface Processing

By creating a convex shape on the mold, it is possible to raise and mold products into convex shapes. This gives the product a three-dimensional feel and a special finish.

-

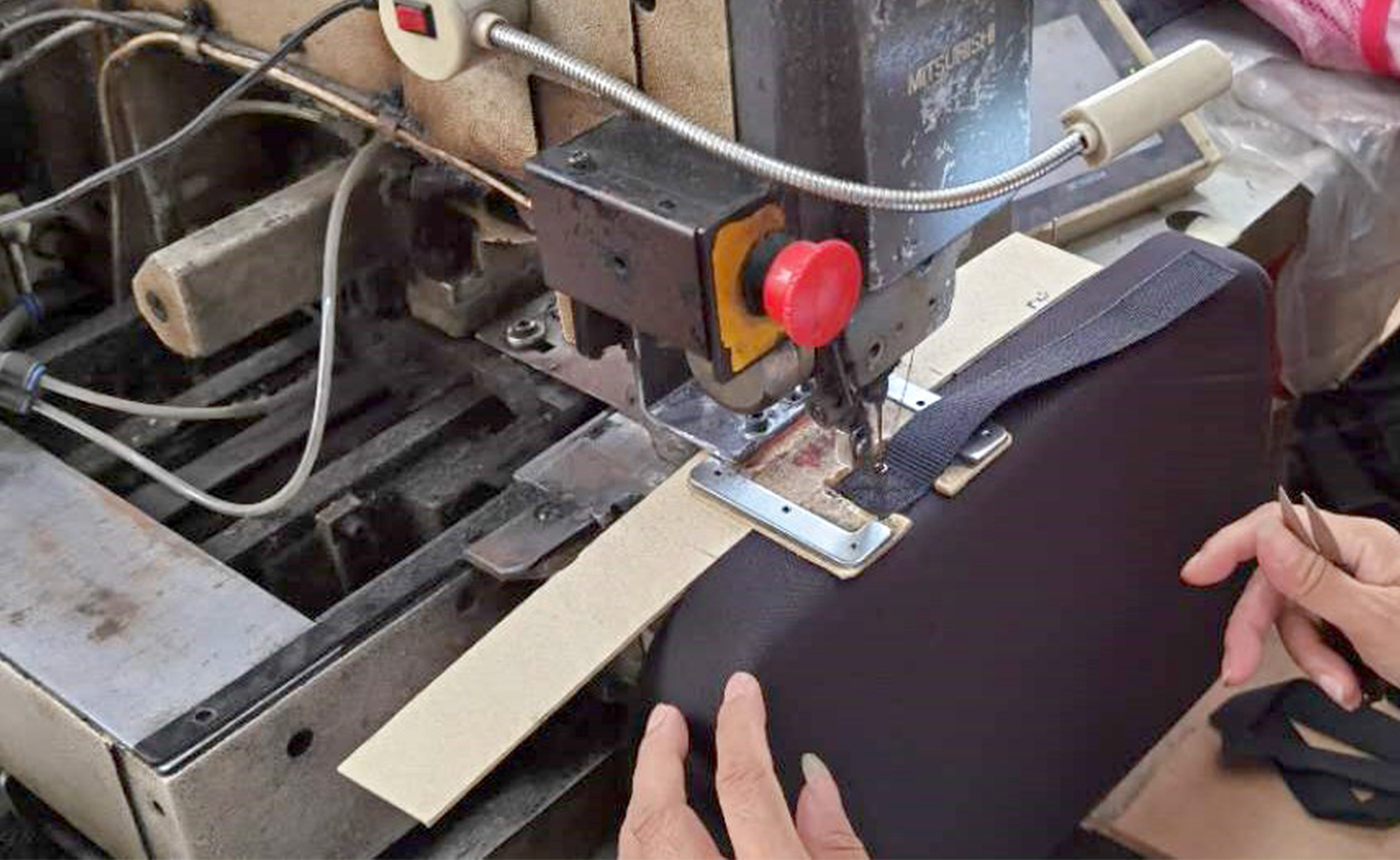

Sewing

Using a specialized sewing machine available for hard materials, it is possible to sew molded EVA to create products such as pouches and bags. Zippers, handles, and other accessories can all be attached. We strictly manage broken needles on the sewing line, recovering and checking for missing parts. We record the date, situation, and name of the sewing operator in the logs to ensure thorough management and prevent any issues.

About the Factory

ISO Certification

Our factory, located in Shenzhen, was established in 2005. It specializes in EVA resin processing and is an ISO-certified facility. With an area of over 2,000 square meters and a workforce of 80 employees, the factory employs advanced manufacturing processes to provide high-quality products tailored to customer needs, ensuring improved product quality and efficient production.

Environmentally Friendly Factory

We minimize waste emissions during the manufacturing process and actively use recyclable materials. For EVA, we use products that have passed SGS testing (one of the world's largest testing and certification bodies). Certification reports and various component lists can also be provided. By focusing on environmentally friendly manufacturing, we contribute to the protection of the global environment.

Pursuing Customer Satisfaction

Our company consistently strives to offer high-quality products that meet customer needs. By focusing on product quality and environmental protection, and pursuing customer satisfaction, we aim to be a trusted factory for our clients.

Equipment

-

Molding Machines (8 units)

EVA sheets are placed between the upper and lower molds, and are molded by pressing the two molds together.

-

Ovens (8 units)

Materials are heated in the oven to soften them for high precision molding.

-

Automatic Mold Grinding Machines (2 units)

The mold is formed by grinding with a high-speed rotating grinding wheel.

-

Fabric Pasting Roller (1 unit)

This equipment is used to paste fabric onto EVA. The weight of the roller ensures firm adhesion.

-

Cutting Machine (1 unit)

This machine is used to cut EVA fabric and other materials to appropriate sizes according to the product specifications.

-

Sewing Machines (10 units)

These specialized sewing machines can sew hard materials like EVA. They are used to manufacture products such as bags and pouches.

What is EVA?

-

High-Quality EVA Material

EVA (Ethylene-Vinyl Acetate Copolymer) is a lightweight and durable material, offering excellent shock absorption and abrasion resistance.

-

Various Applications

EVA thermoformed products are used across a wide range of fields, including sports equipment, footwear, furniture, toys, and industrial goods.

-

Customizable

We offer customization to meet your specific needs in terms of color, shape, hardness, and size. We can also add unique designs or logos.

-

Environmentally Friendly

EVA material is recyclable and has minimal environmental impact, making it a preferred choice for eco-friendly products.

-

Durability and Lightness

EVA thermoformed products combine excellent durability with lightness, making them ideal for daily use as well as outdoor activities.

-

Waterproof and Dustproof

EVA resin material features waterproof and dustproof properties, ensuring reliable use even in bad weather or dusty environments.